25 Jun Lab Fit Out Design Tips for the Food and Drinks Industry

Laboratories in the food and beverage industry are subject to rigid regulations, governed by the necessity for increased food safety, traceability, and adherence to numerous international standards. To ensure that the food and beverage industry is safe and reliable, it must encompass quality control and standardised manufacturing procedures. This in turn necessitates laboratories to ensure they are meeting these quality and manufacturing standards.

Food and Drinks Lab Fit Out – 9 Design Tips

1. Specialist Equipment for Laboratory Set Up

Specialist equipment like microscopes, incubators and refrigerators are useful for the testing and investigation of food and beverage samples. Particularly for brewing, equipment is important for microanalysis and microbiological control, raw material analysis, and yeast management. It is important to ensure the equipment used is appropriate for the testing required and is maintained adequately.

2. Specialist Furniture for Food and Drinks Labs

Within a laboratory it is necessary to have dedicated areas with appropriate furniture for sample preparation, experimentation and analysis.

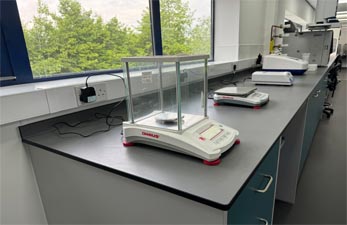

Fixed benching may be specified to accommodate specialist equipment. The weight and depth of the equipment should be factored into the furniture design and the supporting steel framework should be tailored to suit requirements. Cleaning stations are a necessity to maintain hygiene standards. For any wet processes, fitted furniture is necessary to house sinks for washing equipment and glassware.

For most food and drinks laboratories, it is advisable to have a proportion of fitted modular bench units with fixed steel framework in combination with mobile laboratory furniture which can be easily rearranged to provide the flexibility required for a modern facility.

It is important to make provision for storing equipment, ingredients and samples. It may be possible to store these below the bench tops in drawers, cupboards or mobile cabinets. In some cases, reagent shelving is specified which is fitted above and to the rear of the workspace to provide additional storage for smaller items or ingredients.

It may be necessary to add areas of specialist roller racking in order to accommodate extensive ranges of catalogued ingredients which could vary significantly in size from 25 ml up to 1 litre.

Ergonomic seating options designed for laboratory use are beneficial to provide adequate support for scientists throughout lengthy hours of testing and analysis.

3. Worktop Specification for Food and Drinks Labs

Consideration should be given to the laboratory worktop, depending on the specific tasks of the scientists. Moisture resistance should be taken into account for any labs where liquids are in frequent use and some worktops offer benefits if you are working in a sterile environment.

It is also advisable to opt for a worktop material which is easy to clean and maintain, which offers benefits in a food and drinks environment.

4. Flexible Fit Out of Your Laboratory

Having a flexible lab design ensures efficiency and allows for any changes to the layout to accommodate future requirements.

The spacing should be optimised and there should be adequate room to accommodate technical staff with some allowance for growth in staffing numbers. It may be appropriate to include a tasting area within the lab for employees and visitors.

5. Fitting Out a Lab – Health and Safety Considerations

Ensure that there is a safe entrance and exit. There should be enough space to allow for safe movement around the laboratory, minimising possible injury of employees. Appropriate storage should be provided for the management of corrosive chemicals and emergency response equipment like eyewash stations and spill kits should be fitted. Safety in the workplace is also improved by good lighting, controlled temperatures and a well-ventilated environment.

6. Prioritise Hygiene

Laboratories for the food and drinks sector must comply to food safety standards and maintain high levels of hygiene.

Hygienic cladding is a good option for meeting rigorous hygiene standards and is easy to keep clean. Using materials like epoxy resin, phenolic resin or stainless steel for furniture and surfaces maintains cleanliness and helps limit bacterial growth.

7. Lab Ventilation Systems

Food and beverage labs must have adequate ventilation systems for good air quality, managing odours and reducing harmful emissions from the workspace. Air conditioning systems within the lab also contribute to creating a comfortable working environment for employees.

8. Branding for Laboratories

Branding may be an important consideration for companies designing their food and drinks lab. At Klick, we can supply glass partitions showcasing the company’s logo, as a distinguishing branding element. This builds on brand recognition, adds a level of professionalism to the lab design and helps with building a team spirit to encourage lab staff. Alternative branding options are wall murals, custom wallpaper or the use of brand colours in furniture as highlights in breakout and lab spaces.

9. Laboratory Information Management Systems (LIMS)

Food and drink companies have complex systems in place to ensure efficient, reliable and safe lab conditions and manage storage of their materials and products. As part of the design process it is worth considering which type of system to opt for as this may have an impact on the level of cabling and data required.

Food and Beverage Lab Fit Out Example Project:

Klick recently completed an exciting project with Bevie, which manufactures, wholesales, and distributes some of the most famous products for the commercial alcoholic drinks sector and home brewing industry worldwide. Klick converted their outdated laboratory into a flexible and technical facility that accommodates up to 8 staff. This new lab is designed to support various research and development activities for Bevie.

Equipment and Processes

A key component of this project was to understand the distinct processes and materials necessary for Bevie’s research into fermentation systems and alcoholic beverage development. Klick worked closely with the research and development team at Bevie to formalise a proposal to include all their requirements, to improve the workflow and create a lab design to address their specific needs.

The lab was designed to support a range of processes in the alcoholic beverage industry including flavour application work, beer colour and bitter analysis and chemical analysis of yeast congeners. Specialist gases are essential to the lab processes, these included hydrogen, helium and nitrogen. Klick co-ordinated the disconnection and management of the gases throughout the project.

Bevie required specialist equipment essential for analysing alcoholic beverages including a Gas chromatograph with flame ionisation detector, a UV-Vis spectrophotometer with specialist beer analysis software, an automatic titrator, a pH metre, an alcohol and extract metre and a phase-contrast optical microscope. This equipment facilitates the analysis of acidity fermentation degree, density and yeast viability to ensure product excellence.

The design of the furniture had to take into account the specification of the equipment and the power and data provision was specified to accommodate all the equipment required.

Laboratory Furniture for Bevie

The research and development team at Bevie requested a large proportion of fixed furniture which accommodates storage and provides a stable base for their wide range of testing and analytical equipment. Peninsular units extend into the lab space which provide workspaces for the scientists to record results and upload data. These units are fitted with reagent shelving immediately above the work area to allow resource material and ingredients to be stored where they are easily accessible.

The brew room is separated by a glass partition as it has its own air conditioning unit for temperature control. Bespoke Trespa shelving was designed to help with the management of the large conical fermentation vessels which were previously located on the floor. This caused access and handling issues for the lab technicians but these processes have now been improved since the new lab has been in action. Additional practical features in the brew room included floor to ceiling hygienic cladding to prevent staining from the frequent use of red wine and whiskey and coved flooring to prevent any leaks to the floor below.

One end of the main laboratory has a more flexible layout which includes 2 robust mobile workstations which are fitted with reagent shelving. The units have robust lockable levelling castors which allow them to be wheeled to an alternative location and locked securely into position. The mobile workstations have a daisy chained electrical system so they can be connected to mains power in multiple locations.

A mobile tasting table is also located in this area. This was an important design feature as their R & D department wanted to accommodate tasting sessions for visitors and clients. The unit has built in storage to accommodate samples and equipment and can be moved to different locations in the lab or could even be wheeled into the office area.

Expanding the Laboratory Space

The footprint of the lab was expanded to accommodate the new tasting area which meant a new glass partition was required. Branding was a priority for Bevie who opted to have their logo etched onto the new glass partitioning. The design and installation of this feature was co-ordinated by Klick.

The old partition was left in place for as long as possible to act as a barrier from the working office and the installation was scheduled with the Bevie staff so they could plan accordingly and minimise disruption.

Klick’s detailed understanding of laboratory construction allows us to offer a highly efficient fit out service for our clients. This was highlighted in the project at Bevie where we created an environment to perfectly suit the client’s needs and process criteria allowing Bevie to stay ahead of the curve and lead innovation into alcoholic beverage development.

Testimonial

“The project management and communication was exceptional. The level of detail from scope through to costing, including the interviews they held with staff, it was all superb. Having one point of contact throughout the project has meant that Liam is really in tune with our values and requirements from a business point of view. The turnkey solution meant the hassle of co-ordinating the project was minimal, allowing me to focus on managing Bevie and not the detail of the project delivery. There were challenging conditions as the lab is attached to a working office but sincerely, the delivery from Klick, from concept to completion has been outstanding and we can’t wait to show off the new labs to our clients. To be honest, I was doubtful about whether Klick could achieve the timeline however they were one day ahead of schedule so in my eyes, they’ve overachieved!”

Dave Ditcham, General Manager, Bevie, Ellesmere Port

Click here for further details on the laboratory fit out for Bevie

Our consultants will be happy to discuss your food and beverage laboratory design project and the steps required to ensure the success and integrity of your lab operations. Please call 0161 998 9726 or contact us by email to arrange a consultation.

Sources and Further Reading:

The Laboratory Needs of the Food and Beverage Industry

https://www.labmate-online.com/news/it-solutions/2/thermo-fisher-scientific-uk-ltd/the-laboratory-needs-of-the-food-and-beverage-industry/5752

How to Start a Brewery Lab in 2022

https://www.onepointesolutions.com/blog/beer-lab/

What Are The Key Elements of a LIMS for Food and Beverage?

https://www.lablynx.com/resources/faqs/what-are-the-key-elements-of-a-lims-for-food-and-beverage/

Bevie

https://bevie.co/about/