25 Sep Laboratory Fit Out Repurposes Former Top Gear Studio

Our contracts team couldn’t believe their luck when it turned out that access to the latest laboratory fit out project involved driving on the Top Gear track at Dunsfold aerodrome.

Our contracts manager couldn’t resist taking a spin round the Top Gear track whilst the video crew were on site to film progress on Klick’s project.

Whilst carrying out the refurbishment works the track was still used for testing cars and the site was also a fully operational airfield receiving flights. So, when Klick won the contract there was considerable excitement on several counts.

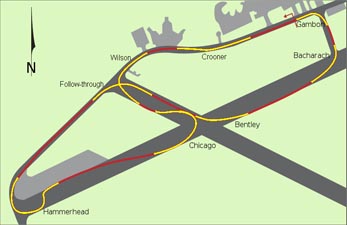

The track’s route started on the perimeter road outside the Top Gear studio. It was marked out by painted lines and structures such as stacks of tyres and was originally created by test drivers from Lotus. The layout of the track was designed to be an equaliser for cars and included some considerable challenges including the infamous Gambon corner which was the final turn before the finish line.

History of the Aircraft Hangar Prior to Fit Out of Labs

The disused aircraft hangar selected for the laboratory fit out has significant heritage. It was used by BAE Systems as a paint shop and the Dunsfold site was owned by BAE Systems until 2002. Originally, Dunsfold was a Canadian wartime airfield constructed over a period of just nine months in 1942.

Allied Supreme Commander General Eisenhower visited Dunsfold in 1944 to inspect the Mitchell Bombers and boost the morale of the Air Crews who would be supporting the D-Day invasion.

In 2002 the site was repurposed as the BBC Top Gear studio and the series was filmed at that site until 2020.

Fit Out of New Engineering Labs by Klick Laboratories

The laboratories were to be located in the aircraft hangar initially used as the film studio for Top Gear.

Klick were contracted By AFC Energy to provide a technical solution for the conversion of the 12,000 sq ft empty hangar.

AFC had outgrown their existing facilities and the building was to be transformed into 5 state-of-the-art laboratories suitable for hydrogen fuel cell manufacturing.

When it comes to lab construction for the engineering sector, attention to detail and precision are key factors that can make a significant difference in the success of projects.

The facility required pressurised sealed labs and Klick managed the installation of the heating, ventilation and air conditioning (HVAC) system necessary to provide the optimal environment to support AFC’s activities.

Klick were responsible for managing all mechanical & electrical aspects of the project along with the installation of specialist gases.

Other technical features to complete the modernisation of the building included Cat 6 E cabling, fob entry to labs/new corridor and a specialist PIR system with recessed microwave sensors.

Fit Out Creates Flexible Environment for Laboratory Staff

Flexibility is key in any research environment and modular mobile workstations were designed which can be relocated with minimal disruption according to workflow requirements to suit the changing needs of the laboratory staff. They can also be used for accommodating and transporting heavy machinery.

Providing engineering staff with the necessary resources and amenities is crucial for their productivity and well-being. Access to dedicated workstations, meeting rooms, breakout areas and collaboration spaces fosters teamwork, creativity and professional growth

Testimonial

“AFC Energy had outgrown our existing lab facilities…. It was essential to design a development facility which could adapt as our production methods and volumes mature, therefore supporting not only our immediate needs but our future strategy. Klick quickly assessed our current requirements and suggested design details to allow us to scale up our future manufacturing functions.

Having used the labs for a few months our technical team are impressed with the functionality and delighted to be working in an environment that ideally suits their needs. We have already benefited from built in flexibility and have reconfigured the lab layout with minimal disruption. This has allowed us to evolve our processes to adapt to the fast-paced environment of hydrogen fuel cell development.”

Dan Hamilton, Manager – Failure Analysis, Characterisation, Testing and Simulation, AFC Energy PLC

Benefits of Refurbishing Existing Buildings for Lab Fit Out

The AFC Energy laboratory facility has seen many different uses over the years and has been given a new lease of life which will benefit AFC for years to come.

Repurposing an existing building for a laboratory fit-out offers significant environmental and cost benefits. By utilising an existing structure, you reduce the need for new construction materials and energy-intensive processes, helping to lower the environmental footprint of the project.

This approach also aligns with sustainability goals by reducing waste. From a financial perspective, repurposing can lead to substantial savings, as the basic infrastructure is already in place. This can lower initial capital outlay and reduce the project timeline, allowing for faster setup and reduced costs associated with delays or construction uncertainties. In the long term, this strategy combines sustainability with financial efficiency, making it an attractive option for businesses looking to create modern lab spaces with minimal environmental impact.

If you have a project in mind to expand your laboratory facilities our consultants will be happy to discuss your options. Please call 0161 998 9726 or contact us by email to arrange a consultation.

Sources and Further Reading:

Wikipedia

https://en.wikipedia.org/wiki/Top_Gear_test_track

Dunsfold Airfield History Society

https://dunsfoldairfield.org/top-gear/

Jonathan Paul Green Set Design

https://www.setdesign.tv/studioshows/topgear

BAE Systems

https://www.baesystems.com/en-uk/heritage/dunsfold-and-langley

AFC Energy

https://www.afcenergy.com/